They are

resistant to UV rays

Resistant to

low temperatures

Small coefficient

of friction

They are

resistant to UV rays

Resistant to

low temperatures

Small coefficient

of friction

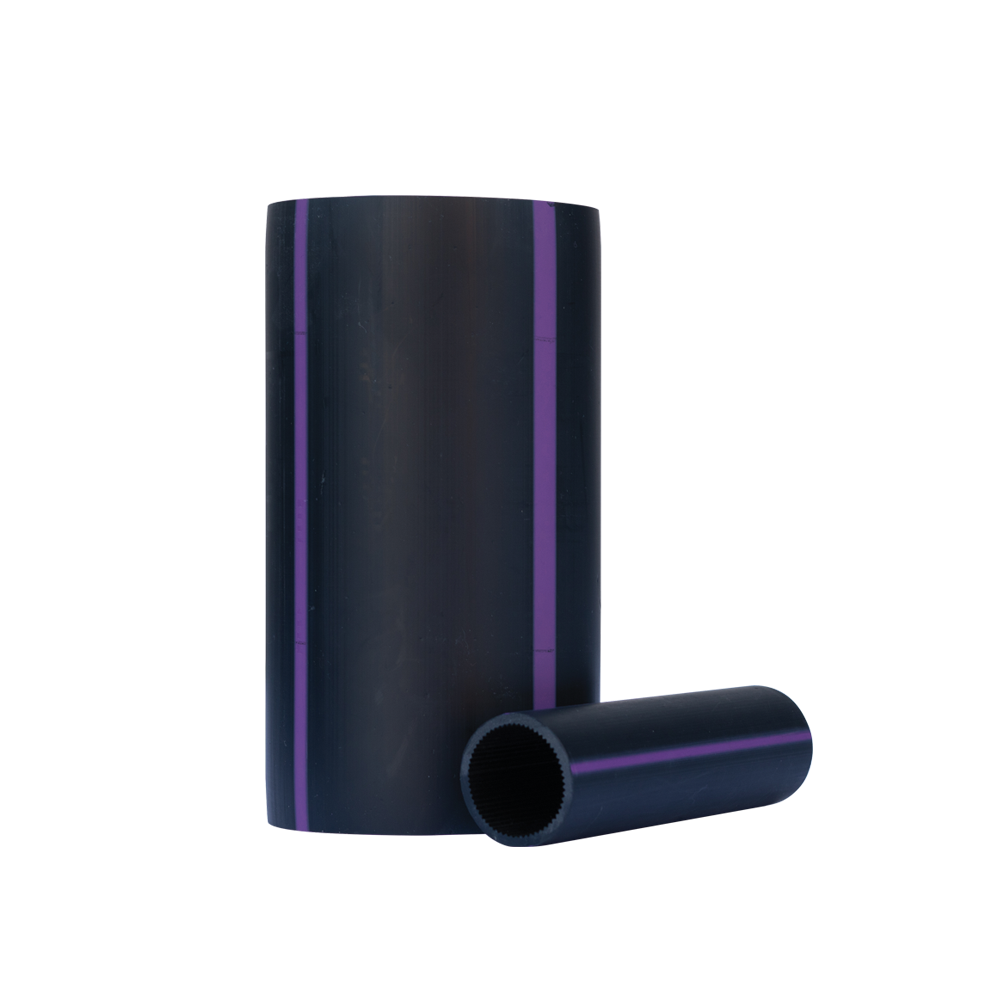

Polyethylene PE80 pipes are used for the construction of cable sewers. The production and quality control is in accordance with the applicable standards SRPS EN 12201-1 and SRPS EN 12201-2 and in accordance with the Technical conditions for small diameter polyethylene pipes for cable sewers ZJPTT. The numerous advantages of polyethylene pipes compared to other materials result in their increasingly wide application.

Advantages

The advantages of polyethylene pipes PE80:

• They are easy to transport and install

• They adapt well to the terrain

• They have a low coefficient of friction

that causes low pressure losses

• The pipes are resistant to UV rays and temperatures from -30°C to +60°C

• They are resistant at low temperatures

Intended use

Polyethylene PE80 pipes, which are used to make cable ducting, are primarily intended for routing and protecting optical cables, telecommunications and power cables in local and regional networks.

Description

PE pipes are single-layer with a homogeneously structured wall, they have a grooved inner surface and a smooth outer surface. Pipes with a diameter of DN20 to DN110 mm can also be produced as two-layer, with a white inner layer. The tube colour is black with purple longitudinal co-extruded lines. The nominal pipe diameter (DN) is the outside diameter (OD) of the pipe